- HomePage

- About Us

-

Product

- Horizontal conveyor

- Vibration feeder

- Disc feeder

- Large angle hoist

- products conveyor

- Bucket elevator

- Bowl type elevator

- other

- Large material warehouse

- Packaging production line

- Quick reverse horizontal conveyor

- Disc spiral feeder

- Bottle sorting machine

- Spiral blade conveyor

- Bottle conveyor line

- Potato chip production line

- Disc machine

- Circular storage bin

- Elevator

- Conveyor

- News

-

Video

- Tip Z shaped elevator

- Bucket C-shaped elevator

- Work Platform

- High angle conveyor

- Bowl elevator

- Fast reverse horizontal conveyor

- Spiral van conveyor

- Disc Blender

- Vibration electromagnetic feeder

- Independent chain plate horizontal feeder

- Bottom conveying line

- Belt turning machine

- Products conveyor

- Horizontal conveyor

- Circular spiral distributor

- Vertical belt elevator

- Single bucket elevator

- Flexible chain conveyor

- Packaging System Solutions

- Machining center

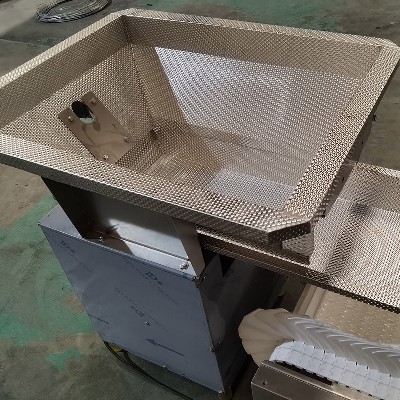

- Vibrating combined scale

- Other products

- Alibaba Store

- Contact Us

- HomePage

- About Us

-

Product

- whole

- Horizontal conveyor

- Vibration feeder

- Disc feeder

- Large angle hoist

- products conveyor

- Bucket elevator

- Bowl type elevator

- other

- Large material warehouse

- Packaging production line

- Quick reverse horizontal conveyor

- Disc spiral feeder

- Bottle sorting machine

- Spiral blade conveyor

- Bottle conveyor line

- Potato chip production line

- Disc machine

- Circular storage bin

- Elevator

- Conveyor

- News

-

Video

- whole

- Tip Z shaped elevator

- Bucket C-shaped elevator

- Work Platform

- High angle conveyor

- Bowl elevator

- Fast reverse horizontal conveyor

- Spiral van conveyor

- Disc Blender

- Vibration electromagnetic feeder

- Independent chain plate horizontal feeder

- Bottom conveying line

- Belt turning machine

- Products conveyor

- Horizontal conveyor

- Circular spiral distributor

- Vertical belt elevator

- Single bucket elevator

- Flexible chain conveyor

- Packaging System Solutions

- Machining center

- Vibrating combined scale

- Other products

- Alibaba Store

- Contact Us

- 中文 | English

PRODUCT CENTER

COMPANY PROFILE

The conveyor equipment developed and produced by Zhongshan Xianbang Intelligent Machinery Co., Ltd. closely meets market demand, combines market trends and years of technical experience, and is committed to providing practical guidance for domestic and foreign agents and large, medium, and small manufacturers, saving customers money, effort, and worry; Tailored according to the actual transportation needs of customers' materials, specially customized transportation equipment production lines; Provided cost-effective and labor-saving unmanned and automated production solutions

NEWS CENTER

Lifting Machine Disc Feeding and Sorting Machine

01/22

2026

Small bag packaging machine enterprise: innovation driven, leading the new future of the packaging industry

01/13

2026

How to transform and upgrade vertical packaging machines, and bravely shoulder the important task of building automatic packaging machinery in the era

01/04

2026

Bucket elevator company leads industry innovation

12/26

2025

Packaging machinery is advancing rapidly

The new vertical pellet packaging machine brings various advantages to the enterprise!

07/15

2025

Working Principle and Advantages of Granule Packaging Machine

07/09

2025

Automatic granule packaging machine: help the development of food industry innovation tool

05/14

2025

Design requirements for unpowered roller conveyors

05/10

2025

Industry application areas of a fully automatic granule packaging machine